Projects

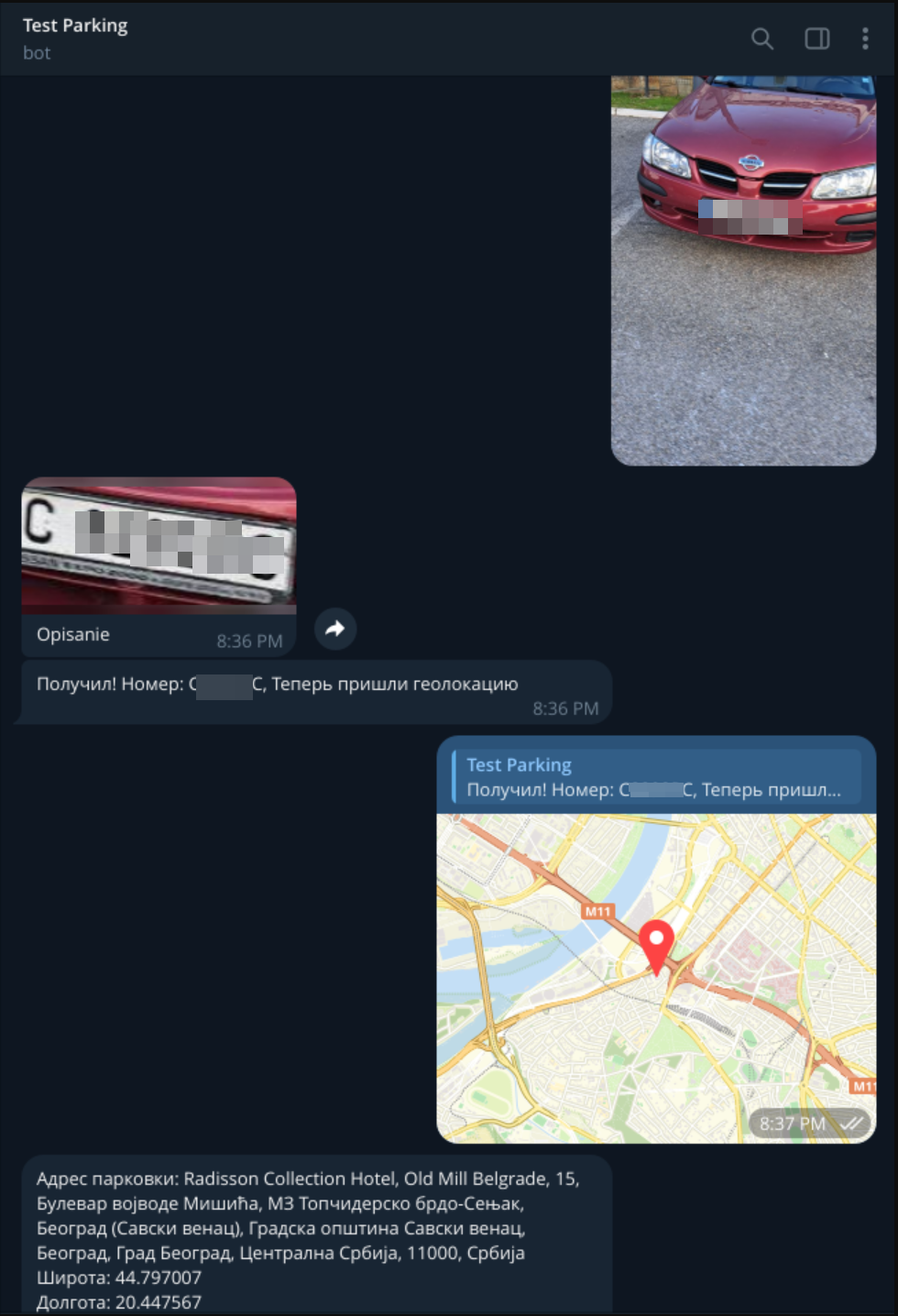

Application, service and neural network models ensemble for car plates OCR

|

|

| Application example in Telegram | |

Description

The goal of this project was to showcase the full development process of a computer vision system, and we ended up creating a mini-Telegram app that can remember where your car is parked. The final part of the project was done as part of the TON x ETH Belgrade hackathon.

The project has three main parts:

- Neural network to segment the car number plate area (part 1)

- Neural network for recognizing characters from the car plate area (OCR, or optical character recognition, part 2)

- API service that combines the two models (part 3)

- Example of using the three parts together in a Telegram bot (for the hackathon)

For the API tests please use:

john_smith nfq2hl5ty39bvcgxal

Technologies: Computer Vision, CVAT, OCR, Segmentation, CI/CD, MLOps, PyTorch, Python, OpenCV, FastAPI, Nginx, DVC, Pytest, ONNX, Docker, Dependency Injector

Links

Other Participants

Firs 3 part of the project were done by myself. For the TON x ETH Belgrade hackathon (4th part of the project) command is:

- Dmitrii Iunovidov - software developer

- Elizabeth Iunovidova - web developer, design

- Veronika Khasanova - project-manager

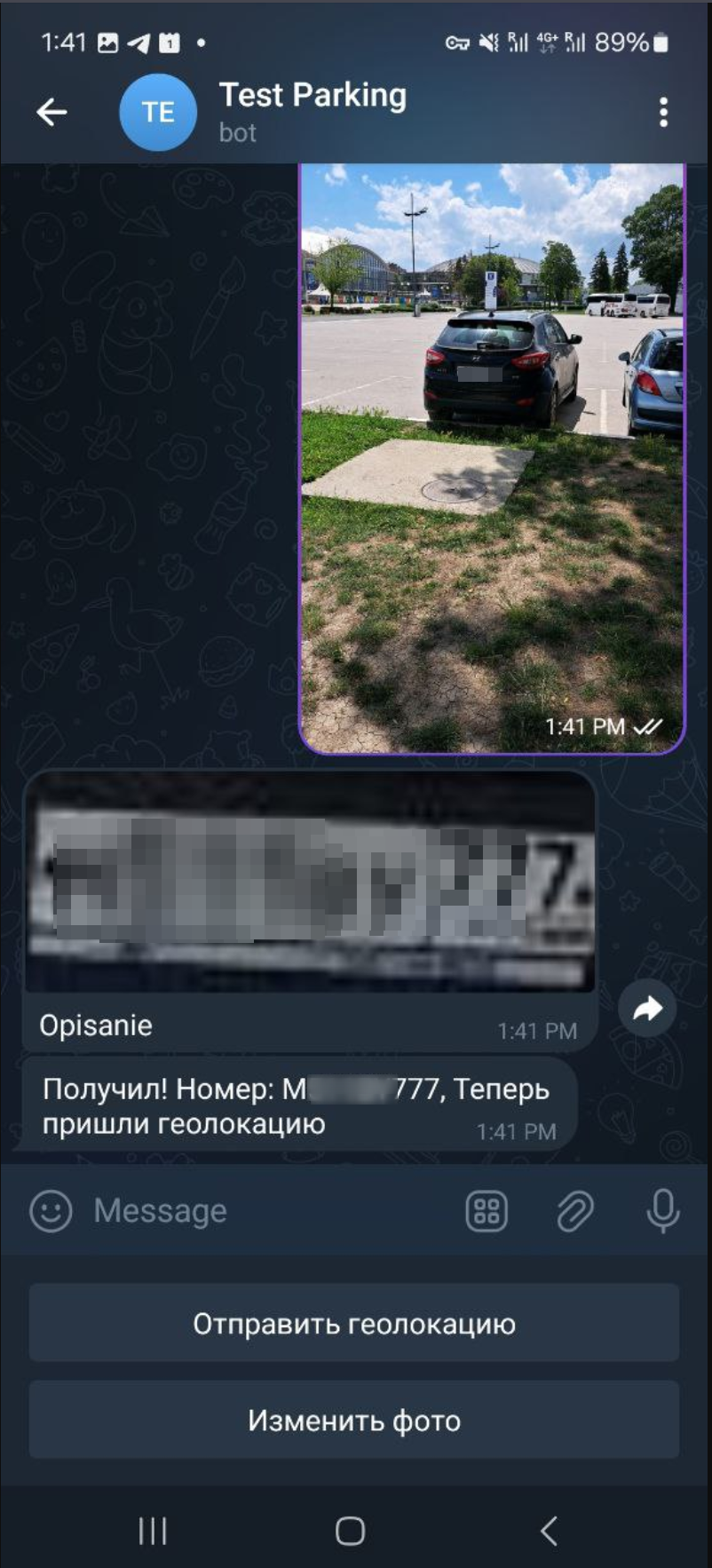

Service and model for Amazon forest satellite images multi-label classification

|

|

| Example of the legal and illegal mining satellite images and image tile for NN network | |

json output for tile on image (type of image and probabilities):

{

"primary": 0.9996139407157898,

"cloudy": 0.9987779855728149,

"partly_cloudy": 0.9978551864624023,

"water": 0.015077352523803711,

"agriculture": 0.014799944125115871,

"road": 0.006275194231420755,

"cultivation": 0.003983434289693832,

"blow_down": 0.001087745069526136,

"bare_ground": 0.0008568777120672166,

"clear": 0.0004581456305459142,

"slash_burn": 0.0004100436926819384,

"habitation": 0.00034076423617079854,

"selective_logging": 0.00032725848723202944,

"blooming": 0.00027702274383045733,

"haze": 0.00023074859927874058,

"conventional_mine": 0.00014223616744857281,

"artisinal_mine": 7.872955393395387e-06

}

Description

This was a project to classify satellite images. We trained a neural network and created an API to do it. The project have two parts:

- Neural network for multiclass classification.

- API service for the model.

For the API tests please use:

john_smith nfq2hl5ty39bvcgxal

Technologies: Computer Vision, Multi-label Classification, CI/CD, MLOps, PyTorch, Python, FastAPI, Nginx, DVC, Pytest, ONNX, Docker, Dependency Injector.

Links

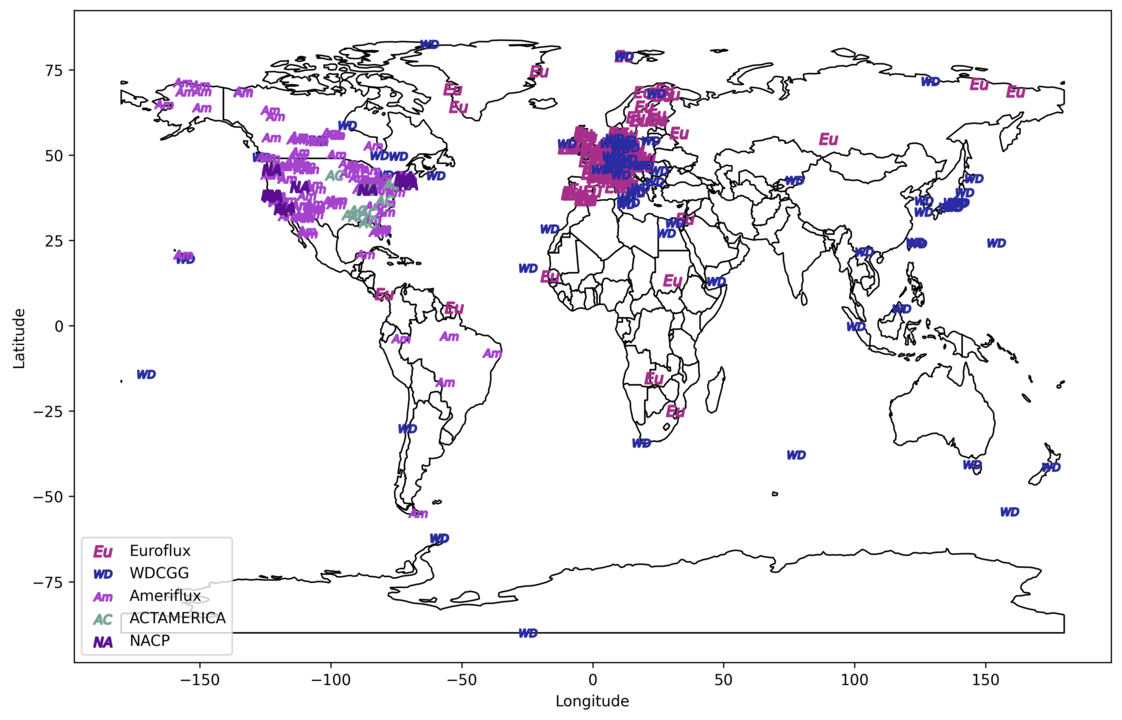

WEB climate and CO2 data acquisition system

|

| Map with all ground station in datasets for CO2 data from 2007-2021 |

Description

Web software, which is based on jupyter notebook for get CO2 and climate data for selected coordinate point. This is my test project to show some skills with geodata and jupyter app.

Technologies: jupyter, Python, pandas, geopandas, matplotlib, numpy, ipywidgets, voila, Nginx.

Links

LogicYield LLC Startup

|

| Startup logo, company was started in 2022 |

Description

As part of our work with mineral fertilizer and computer vision, we created the startup "Logic Yield". We develop software and hardware systems for industrial production, which we can use to dynamically control pellets. We also have an API that can be integrated into any plant information system (PI System, data PART, and more)!

Links

Other Participants

- Veronika Khasanova - CEO

- Dmitrii Iunovidov - cofounder, software engineer

- Elizabeth Iunovidova - cofounder, web-developer and technology engineer

- Alexey Bakhvalov - engineer

- Valery Iunovidov - maintenance engineer

- Ikechi Ndukwe - intern, ML-engineer

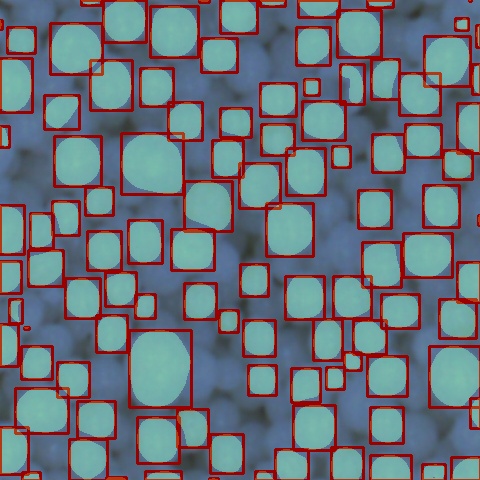

Robotic system of granules optical control DotPulse

|

|

| Robotic system of granules optical control "DotPulse" and example of granules recognition | |

Description

The device use image with granules to calculate its size from 1 to 100 mm. It can analyze physical properties like the linear size of the particles, their shape, and color (it detects at least 90% of particles, with an error of 3.3% between parallel measurements for particles between 2 and 5 mm). Device also works in different spectrum ranges, like UV, visible light, and IR.

Technologies: Computer Vision, Instance Segmentation, CI/CD, MLOps, PyTorch, Python, OpenCV, FastAPI, Nginx, DVC, Pytest, ONNX, Docker, Dependency Injector

Links

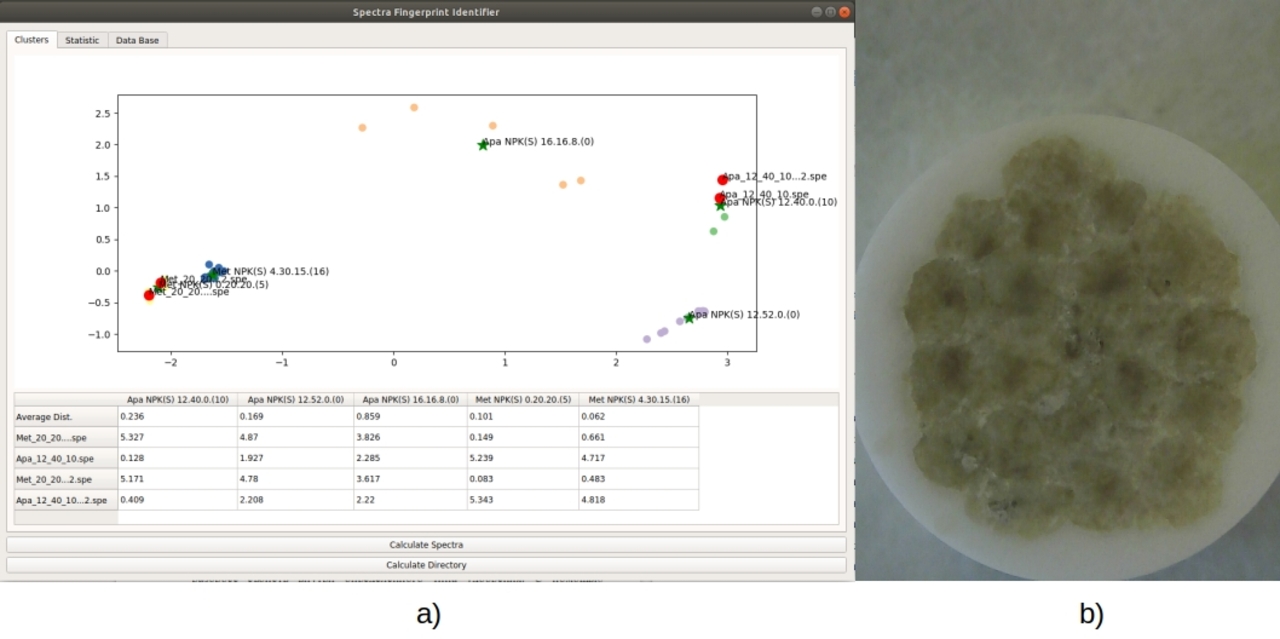

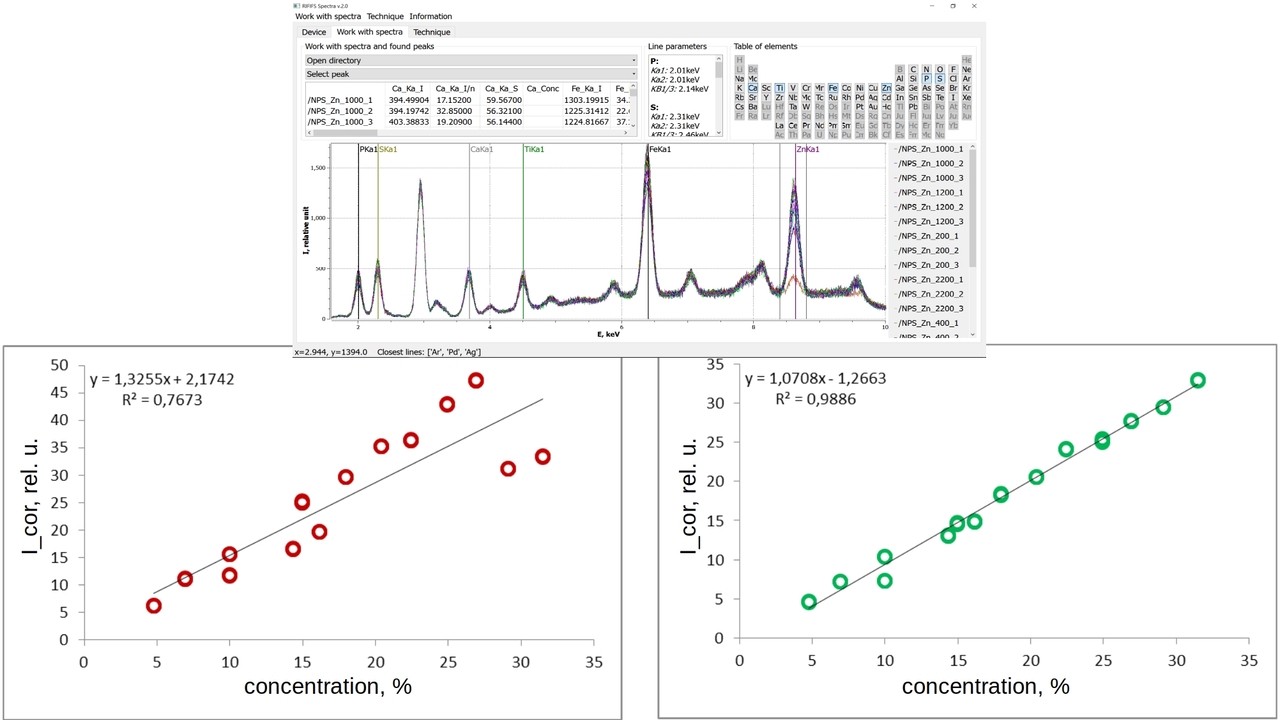

Analysis of mineral fertilizers by "fingerprints" technique (spectral data, classification, clusterization)

|

| "Fingerprint" analysis and identification of the fertilizers. a) software with clusters of fertilizers (manufacturer and brand); b) prepared fertilizer sample (pressed granules on boric acid substrates). |

Description

Express identification of mineral fertilizers manufacturer and "standartiness" with energy-disperse X-ray fluorescence spectra (ED XRF):

- determine manufacturer based on XRF spectra

- determine if sample is related to good one ("standartiness")

- automated software for specific XRF spectra processing

- develop technique for unknown sample identification

- describe XRF spectrometers for such project

Technologies: PyQt5, k-means,

$\chi^2$, openCV, matplotlib.

Links

- III All-Russian Conference on Analytical Spectroscopy with International Participation

- Mathematical and computer modeling in materials science

Other Participants

- Dmitrii Iunovidov - idea development, software writing and project developer

- Alexey Bakhvalov - ED XRD spectrometers supply for research

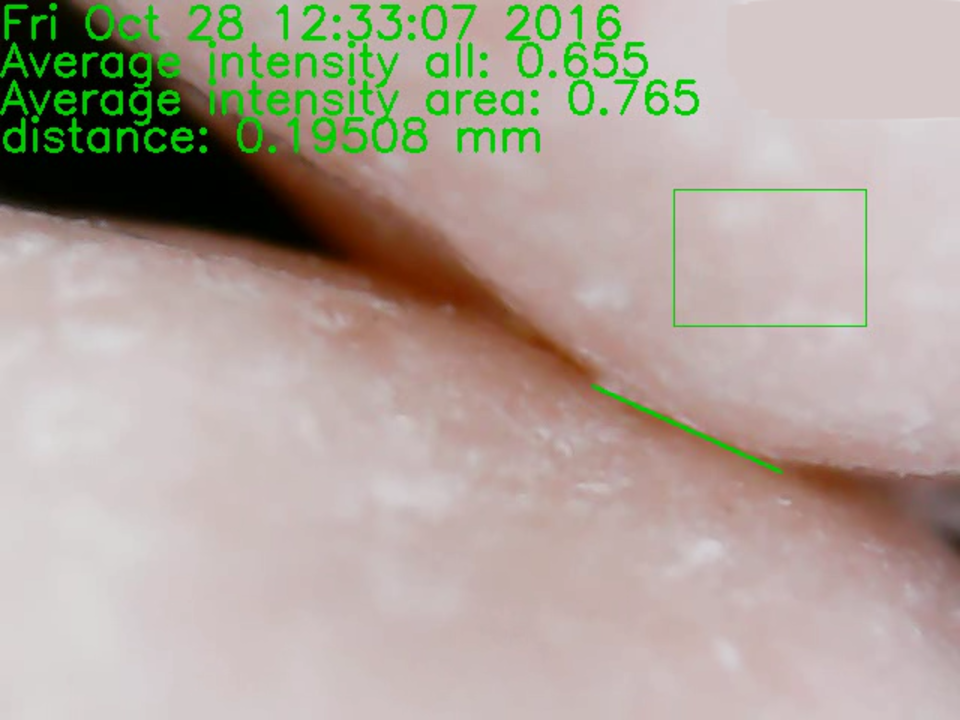

USB-microscope system to study the properties of mineral fertilizer granules

|

Example of caking granules (in software) |

Description

A hardware and software system has been created that lets you watch, record, and analyze tiny objects over time (color, surface texture, reflections, etc.). We did the research with granules of fertilizer under normal conditions and in a controlled environment.

With such tool, we were able to see the "ring effect" (moisture buildup at the point where two granules touch, with a spherical shape).

Technologies: PyQt5, OpenCV

Research and Testing Center "Control Technology"

|

|

| Created laboratory in Cherepovets State University for ESG project and ecology data analyses (before and after) | |

Description

A project for a scientific testing lab based at the Department of Chemical Technology at Cherepovets State University has been created and implemented to provide independent quality control for industrial products, with a focus on international standards and best practices.

The project deals with ESG (environmental, social, and governance) issues, as well as artificial intelligence and physico-chemical testing methods. It was my own personal project that was developed from scratch and approved by the university's scientific, technical, and academic councils.

Links

- 1st place in the corporate competition "Young Leader" at JSC "Apatit" and 3rd place throughout "PhosAgro" Corporation

Other Participants

- Dmitrii Iunovidov - developing and implementation of the project. Organize of laboratory preparation and repair.

- Ekaterina Tselikova - Vice-Rector for Science of ChSU, active assistance in promoting the project.

- Oksana Kalko - Chief of Chemical Technology department of ChSU, active assistance in promoting the project.

- Konstantin Aksenchik - Assistant Professor of Chemical Technology department of ChSU, active assistance in promoting the project.

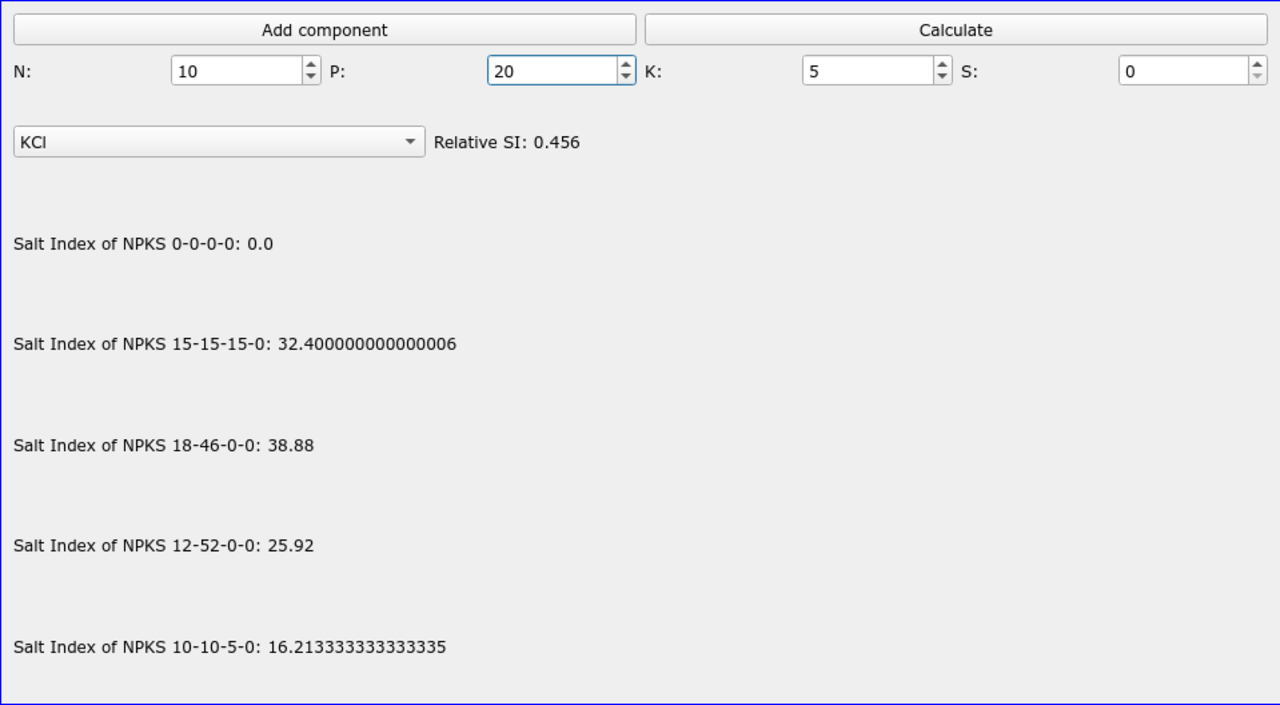

Modified salt index parameter for mineral fertilizers

|

|

| Example of "Salt index calculator" software with "salt index VS chemical elements" correlations | |

Description

An existing parameter has been modified to assess the salt effect of fertilizers (how strongly they absorb moisture from the soil and crops).

In the industrial and scientific literature, there is such parameter as "salt index" (SI) for assessing the salt effect of mineral fertilizers. However, this criterion, proposed by D. Mortved in 1943, is already outdated and is not informative. Over the years, there has been considerable confusion in determining SI (osmotic pressure of soil solutions, conductivity of soil solutions, conductivity of solutions on water, etc.).

We decided to modify this parameter to meet modern requirements and make its calculation more accurate and representative. An additional task was to provide the possibility of experimental calculation of the salt index (for a more representative calculation and the possibility of certification of measurement methods).

The parameter reflects the conductivity of soil solutions of fertilizers and, according to the literature data, is an additive value. It can be calculated based on tabular data for the main components of fertilizers (in general, their content exceeds 10% by weight). We questioned this interpretation of SI and proved that even small impurity compounds in mineral fertilizers can have a significant effect on the osmotic pressure in solution (from 1% by weight).

Links

- Software "Salt Index Calculator"

- Industrial technique for JSC "NIUIF"

- The methodical textbook of the Chemical Technologies Department at Cherepovets State University

Other Participants

- Dmitrii Iunovidov - software and project development

- Maxim Nadezhin - help with software and experiment procedures

- Valery Sokolov and Olga Abramova - assistance in the implementation of measurement technique

- Constantin Aksenchik - revision of the text of the manual, assistance in publication

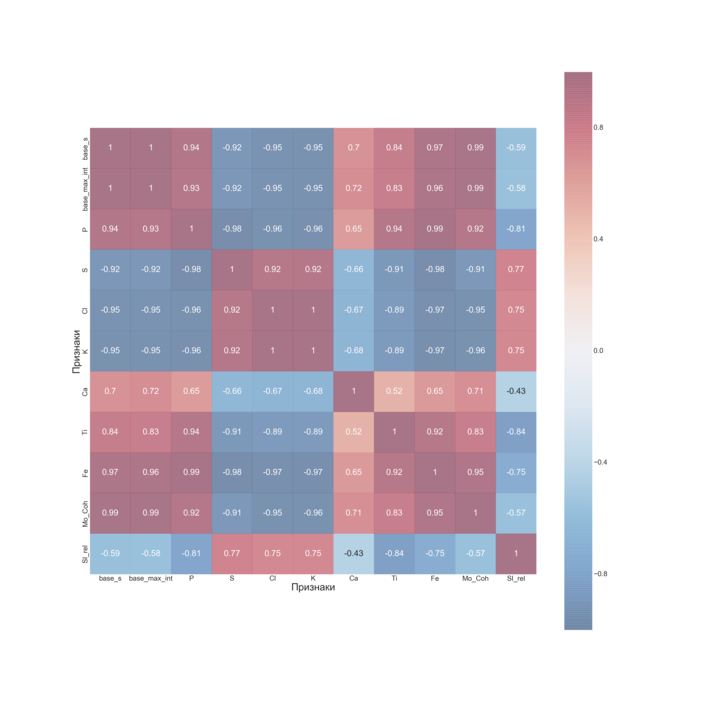

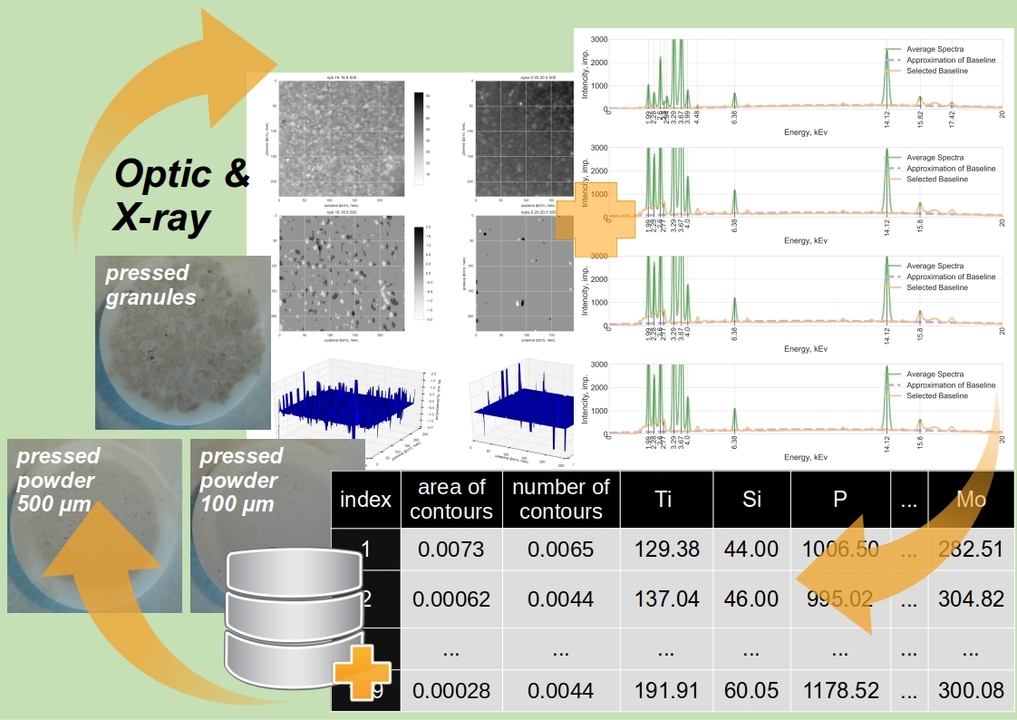

XRF analysis of mineral fertilizers with optical modification

|

Principle of combined optical and X-ray fluorescent analysis of mineral fertilizers |

Description

Conducting a quick analysis of fertilizer for physical and chemical properties, like nitrogen content and fractional composition.

The work was used as the basis for my PhD thesis. I used statistical methods to process a lot of data (about 500 samples and 30 properties), to calculate the quality of industrial fertilizer. These properties can change a lot, and we measure them using a combined X-ray and optical analysis method. We use computer vision to analyze the size and surface of the fertilizer particles. We also looked at different algorithms for predicting the quality and performance of fertilizer, with minimal "manual" preparation of data.

Predicted results of physical and chemical properties of mineral fertilizers:

| N | P | K | S | Fraction | Was dried or not | |

|---|---|---|---|---|---|---|

| Values Range |

[0; 16] mass % | [15; 52] mass % | [0; 20] mass % | [0; 20] mass % |

granules; pressed: granules or powder < (500 mkm, or < 100 mkm) |

[0, 1] |

| Classification, F-metric (%) | ||||||

| Linear |

99.31 | 99.78 | 99.59 | 99.56 | 92.40 | 72.94 |

| Linear With L1 |

99.65 | 99.78 | 99.57 | 98.87 | 92.51 | 73.08 |

| Linear With L2 | 99.65 | 99.78 | 100.0 | 98.99 | 91.33 | 68.46 |

| Random Forest |

100.0 | 100.0 | 100.0 | 98.99 |

98.40 | 73.37 |

| Most Signif. Feature |

Cl (15.56) |

Ca (17.04) | Cl (14.31) | Ca (20.47) | counters area (25.70) |

P (11.49) |

| Regression, average absolute deviation (mass %) | ||||||

| Linear |

0.39 | 1.12 | 0.29 | 0.70 | - | - |

| Linear With L1 | 0.60 | 1.32 |

0.42 | 1.04 | - | - |

| Linear With L2 | 0.36 |

1.11 |

0.29 | 0.70 | - | - |

| Most Signif. Feature |

K (20.19) | Sr (20.17) | background area (25.44) |

K (17.46) | - | - |

Links

Physical and chemical analyses techniques

|

| Example of using a corrected analytical signal after a multidimensional regression to determine fluorine in AlF3 (ED XRF) |

Description

7 techniques for the analysis of industrial products according to RMG 61-2010 have been developed and certified at the industry and state levels.

Developed techniques:

| Title of method | Basic method | Measuring range, wt. % |

Relative accuracy value, ±δ, % |

|---|---|---|---|

| Analysis of fluorine in industrial aluminum fluoride (AlF3) |

ED XRF | 93.0 – 98.0 | 1.1 |

| Analysis of Si impurities in industrial AlF3 | ED XRF | 0.08-0.40 | 24 |

| P2O5 analysis in crystalline MAP | ED XRF | 48.0 – 62.0 | 1.0 |

| Analysis of P, S, K in PKS fertilizers | Wave XRF | P2O5 12.5 – 25.0 K2O 13.5 – 33.0 S 4.0 – 12.0 |

1.5 3.0 3.6 |

| P2O5 analysis in apatite concentrate | ED XRF | 37.0 – 40.0 | 1.2 |

| Analysis of Al2O3 in nepheline and syenite concentrates | ED XRF | 26.0 – 30.0 | 1.0 |

| Salt index analysis in fertilizers | Potentiometry | - | - |

Other Participants

- Dmitrii Iunovidov - development of the techniques concept, collect of experimental data, statistic calculations

- Evgeria Krylova - writing the text of techniques, statistic calculations

- Olga Abramova - final verification the text of techniques, assistance in techniques development for industrial and state verification